Product development went through some major upgrades in the past few years. On the software side there was the establishment of the Software Development Lifecycle and the widespread adoption of Agile methods. With respect to widget development, companies adopted NPI, NPD, and stage gate methodologies. Systems development embraced the “V” development pattern. All of these improved the ability of organizations to manage product development. But all of them were still looking at the business from an Industry 3.0 (or earlier) perspective.

The literature and buzz around digital transformation and Industry 4.0 is looking at platforms, ecosystems, clouds, AI, VR, Blockchain, IoT, and analytics. But when it comes time to create the next product, the development team is often still using an MRD (Market Requirements Document) to create a PRD (Product Requirements Document) and then a V&V plan (Verification and Validation). All of these are a good idea when you are working with a stable business environment, a known customer need, familiar technology, and a workforce experienced with your industry and processes. Unfortunately, that does not exist for the new digitally transformed Industry 4.0 product lines.

There is an additional complicating factor. Most existing companies do not just turn a “digital transformation switch” and see all their customers and products instantly go from Industry 3.0 applications to Industry 4.0 applications. There are still legacy products out there that have a large market, make a lot of money, and many of the customers want those products for the foreseeable future. The customers would be OK with a minor refresh, but they are generally happy with the product they have. So, a product development organization must be able to develop with Industry 3.0 practices for legacy products and at the same time use Industry 4.0 practices for new product lines. That is not easy.

The culture in the marketing and development organizations must be different to perform at an optimal level in each of those contexts. I have already mentioned some of the characteristics of Industry 3.0 product development. Let us now consider how digitally transforming the product development process changes things. There are significant changes with respect to identifying market needs and product planning. In addition, there are significant changes for the technology and product development processes within the business. On top of that the project management approach is often different.

With respect to digitally transformed marketing and product planning. The challenge is that in many cases, the customer does not yet exist. Or if the customer exists, they do not know what they need because the rest of the ecosystem around them is still developing. Digitally transformed products are connected, with real-time data being exchanged between the product and apps that work with the product. Together, the product and apps open the doors to new activities, new experiences, new industries, and new expectations. For example, I just finished a three-day business trip. On this trip I was using my smartphone continuously in ways that were not even envisioned a few years ago. For new activities I listened to music, podcasts, and watched videos on my smartphone both in the airport and on the plane. For a new experience, while eating dinner at a restaurant I could zoom with my wife who was at home, as though she was sitting across the table from me. Although I rented a car this time, my last trip I took an Uber, which is an example of a new industry. And along the way I was texting people regularly, ordering food from an app and picking it up on my way to the airport, and following the traffic advisories while driving. Oh, and one more thing, I did make one phone call with my smart phone. I do not think the MRD for the first iPhone had most of those items listed.

The digitally transformed marketing department needs new processes to break the paradigms of the current products. They need to envision new customers, doing new activities, having new experiences, and inventing new industries. To hope that any organization can do this with a high degree of accuracy is foolishness. However, the digitally transformed Marketing MRD can envision as many ideas as possible in order to create a product planning document that has open-ended possibilities. This is not precise market segmentation and customer needs analysis; it is envisioning, brainstorming, and networking with organizations throughout the value chain. The best practice I have seen up to this time is to brainstorm customer clusters, map a value chain for that cluster based on digitally transformed services, and then segment the value chain into platforms, apps, and services to be developed.

A marketing organization that is supporting both Industry 3.0 products and Industry 4.0 products would do well to maintain two separate processes. One for products with clarity in the definition of customers, needs, and expectations. The second for products that are full of possibility and ambiguity.

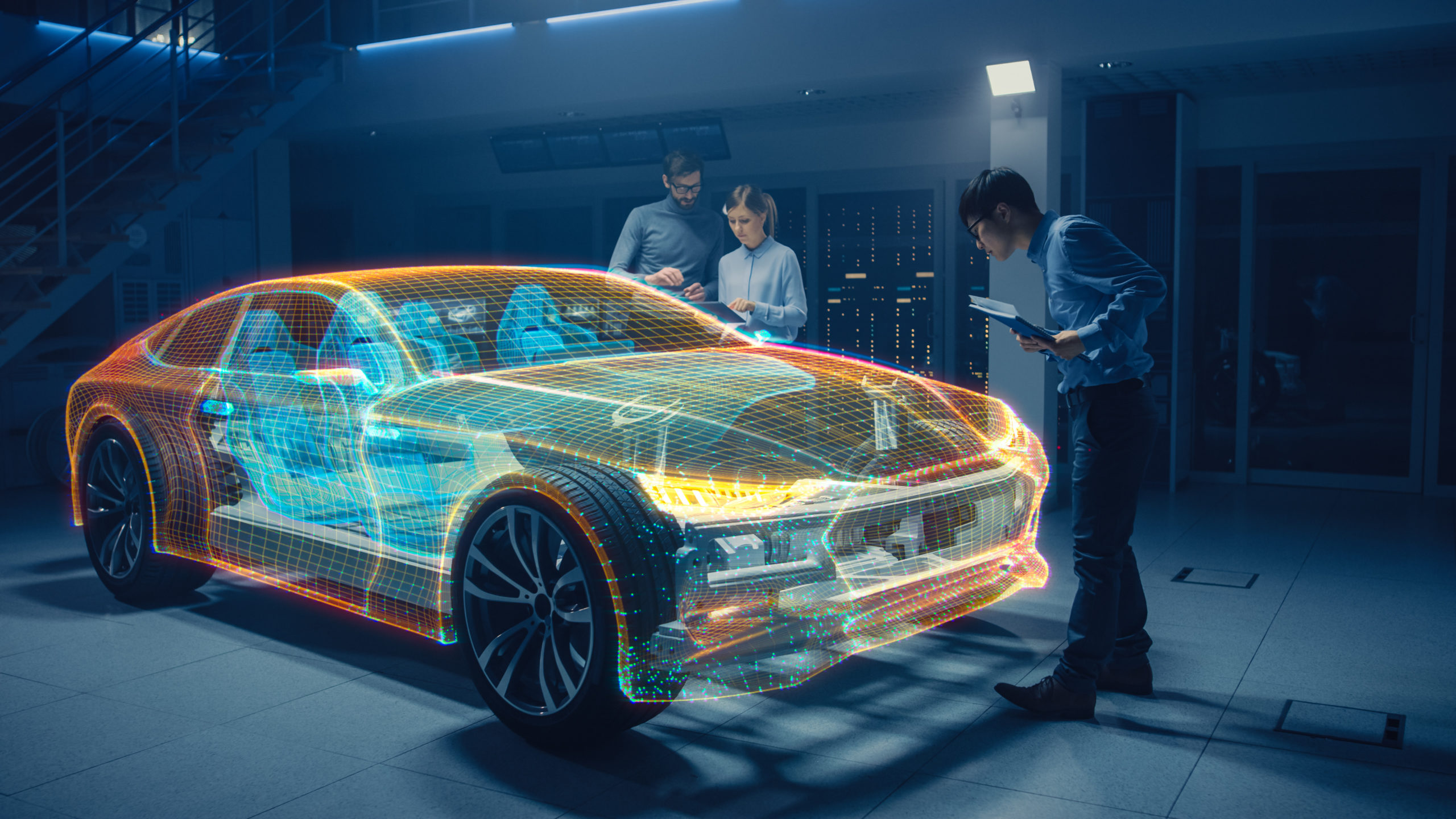

Which brings us now to the technology organizations and product design and development. There are two major design initiatives that are critical elements of digitally transformed product development. One is the use of model-based design. The other is the necessity for an iterative development process. Model based design relies on advanced 3-D modeling and digital twin applications to first invent the product in a digital fashion. With this model, various concepts can be tried to determine the capabilities and limitations of each. The model can be used in a variety of digital applications to assess its performance and to explore new limits, or the absence of limits, on product variants. The model-based design work often comprises several of the early iterations in the development process. Once the iteration of physical development of prototypes or actual coding of software starts, a baseline variant is used. The concept of minimally viable product is embraced by the development team. The product is iterated with the business deciding which of the minimally viable products to commercialize and which to use as jumping off concepts for another generation.

The transition for the new product technical development teams to model-based design is a much easier transition than the one facing marketing. Virtually all technology departments already use CAD systems. The model-based design is the next level up from traditional 3-D CAD design. The engineers can embrace the new approach provided they receive adequate training.

The final aspect that must change is project management. Digitally transformed product development is a dramatic shift in the culture of many organizations. Instead of certainty in requirements and structured development project plans, the new process embraces rapid pivots and constantly changing customer needs and expectations. A few years ago, the acronym VUCA came into vogue in product development. VUCA stands for volatile, uncertain, complex, and ambiguous. A VUCA project was considered high risk and many companies used a high VUCA score as a rationale to cancel a product development project. In the digitally transformed world of Industry 4.0 products and systems, nearly all developments will be VUCA. An organization that must manage both Industry 3.0 projects and Industry 4.0 projects would do well to have two project management methodologies. One for low VUCA (Industry 3.0) which seeks to avoid and minimize risk, and one for high VUCA (Industry 4.0) the embraces risk and uncertainty and leverages that into opportunities.

The big challenges for digitally transformed new product development is in marketing and project management. Engineering design and development organizations will need to invest in an upgrade of their CAD modeling systems, but their basic design rules will not need to change.

Tag/s:Business TransformationDigital EnterpriseIndustrial AgeInnovation